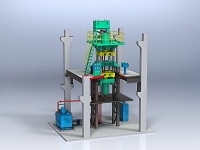

Repair and modernization of press equipment

The INTERMASHSTROY company carries out repair and modernization of heavy hydraulic presses of various degree of complexity. The experience and knowledge of our specialists will not only allow to fully restore its functional qualities, but also bring Your equipment to the modern technical level. The proposed modernization volumes will turn Your worn press into an updated, modern, high-performance machine.

Our team are specialists who have accumulated many years of experience in the design and manufacture of heavy hydraulic presses at the Kolomna Heavy Machine Tool Plant, which one of the areas has always been the design and manufacture of unique press equipment.

Modernization of presses is made according to requirements of modern technologies of manufacturing of products on the press equipment, degree of modernization is defined by the Customer.

The proposed scope of modernization of heavy and unique hydraulic presses:

- Increasing the power parameters of the units;

- Improving the accuracy of the press parameters;

- Increase press productivity;

- Equipping of presses with auxiliary mechanisms for automation of technological processes.

List of works:

- Technical expertise of equipment with recommendations;

- Preparation of technical specification;

- Execution of design works on modernization and reconstruction;

- Production in metal of a repair set of units and parts with the subsequent test at factory and at the customer according to the program;

- Carrying out the supervision of installation or installation works;

- Pre-commissioning activities;

- Training of Customer's personnel;

- Putting the equipment into commercial operation with registration of the necessary document.

The INTERMASHSTROY company carries out repair and modernization of serial and unique press equipment. Our experience and knowledge guarantee the achievement of assigned tasks with minimal costs.

The list of equipment manufactured at the Kolomna Heavy Machine Tool Plant:

EXTRUDING PRESSES

| № | Denomination | Model | Force MN | Pressing speed, mm / s | Diameter of ingot, mm | Length of ingot, mm | Weight, ton |

|---|---|---|---|---|---|---|---|

| 1. | Press for production of pipes made of copper | ПА8340 | 10 | 2…200 | 85…180 | 100…300 | 240 |

| 2 | Press for production of pipes made of copper | ПА8340Р | 10 | 0,2…25 | 85…181 | 100…301 | 240 |

| 3 | Press for production of pipes made of aluminium | П8742БМ | 16 | 0,2…30 | 150…200 | 450…800 | 370 |

| 4 | Press for production of pipes made of aluminium (reverse pressing) | П8842 | 16 | 0,2…40 | 150…200 | 450…800 | 135 |

| 5 | Press for production of pipes made of steel | П8742А | 16 | 400 | 100…150 | 400…600 | 305 |

| 6 | Press for production of pipes made of copper | П8742 | 16 | 2…80 | 150…250 | 3000…700 | 650 |

| 7 | Press for production of pipes made of copper | ПА8742Ц1 | 16 | 2…150 | 150…250 | 300…700 | 650 |

| 8 | Press for production of pipes made of steel | 20 | 400 | 140…180 | 600…700 | 380 | |

| 9 | Press for production of profiles made of aluminium | 25 | 0,2…28 | 195…245 | 400…840 | 520 | |

| 10 | Press for production of bars made of copper | 25 | 2…80 | 180…280 | 300…800 | 800 | |

| 11 | Press for production of bars made of copper | ПБ8744П | 25 | 2…150 | 180…280 | 300…800 | 800 |

| 12 | Press for production of pipes made of aluminium | П8745 | 31,5 | 0,2…30 | 250…280 | 400…850 | 530 |

| 13 | Press for production of pipes made of steel | П8145А | 31,5 | 2…400 | 180…250 | 700…900 | 520 |

| 14 | Press for production of pipes made of copper | 31,5 | 2…60 | 200…360 | 300…900 | 960 | |

| 15 | Press for production of pipes made of copper | ПА8745П-1 | 31,5 | 2…150 | 200…360 | 300…900 | 960 |

| 16 | Press for production of profiles made of aluminium | 35 | 0,3…25 | 215…300 | 600…1040 | 563 | |

| 17 | Press for production of profiles made of aluminium (reverse pressing) | КП535ф2 | 35 | 0,2…30 | 250…410 | 500…1200 | 620 |

| 18 | Press for production of bars made of copper | ПА649А | 50 | 2…150 | 300…420 | 300…1000 | 1200 |

ISOSTATIC PRESSES

| № | Denomination | Model | Force, МН | Working space diameter, mm | Working space height, mm | Working pressure, MPa | Working temperature, С | Weight, ton |

|---|---|---|---|---|---|---|---|---|

| 1 | Hydrostat | КП650 | 50 | 450 | 1200 | 310 | 30 | |

| 2 | Gasostat | ЯО615 | 50 | 320 | 1000 | 200 | 1200 | 75 |

| 3 | Hydrostat | КП651 | 100 | 650 | 1000 | 310 | 90 | 65 |

| 4 | Gasostat | ЯО6016 | 125 | 485 | 1800 | 200 | 1200 | 223 |

| 5 | Hydrostat | ЯО6012 | 160 | 1000 | 1800 | 200 | 180 | |

| 6 | Gasostat | ГУ40 | 400 | 1300 | 1500 | 150 | 1200 | 836 |

| 7 | Hydrostat | Г63 | 630 | 1500 | 1500 | 350 | 942 |

HYDRAULIC SHEET-STAMPING PAD PRESSES

| № | Model | Force, MN | Deforming pressure, MPa | Length of working table, mm | Width of working table, mm | Height of stamped part, mm | Number of tables | Weight, ton |

|---|---|---|---|---|---|---|---|---|

| 1 | КП569 | 50 | 200 | Ф800 | 200 | 1 | 80 | |

| 2 | КП393 | 60 | 100 | 1130 | 600 | 100 | 2 | 70 |

| 3 | КП653 | 150 | 60 | 2500 | 1200 | 200 | 2 | 450 |

| 4 | ЯО6017 | 240 | 100 | 2100 | 1330 | 250 | 4 | 1250 |

| 5 | ЯО6017А | 240 | 100 | 2100 | 1330 | 250 | 4 | 1250 |

| 6 | ЯО6017Б | 249 | 100 | 2100 | 1330 | 250 | 4 | 945 |

HYDRAULIC SHEET-STAMPING DIAPHRAGM PRESSES

| № | Model | Force, MN | Deforming pressure, MPa | Length of working table, mm | Width of working table, mm | Height of stamped part, mm | Number of tables | Weight, ton |

|---|---|---|---|---|---|---|---|---|

| 1 | КП570 | 300 | 60 | 2500 | 1600 | 350 | 2 | 230 |

| 2 | КП623 | 400 | 100 | 3000 | 1200 | 250 | 2 | 350 |

| 3 | ЯО6019 | 600 | 100 | 4200 | 1415 | 250 | 2 | 420 |

PRESSES OF HYDRAULIC TESTING OF PIPES

| № | Model | Pipe diameter, mm | Pipe length, m | Number of positions | Test pressure, MPa | Capacity, pcs / h | Weight, ton |

|---|---|---|---|---|---|---|---|

| 1 | КП611 | 19…114 | 5…10 | 2 | 20 | 200 | 50 |

| 2 | КП146 | 48…146 | 5,5…11,5 | 1 | 125 | 100 | 250 |

| 3 | КП536 | 114…324 | 5…13 | 1 | 125 | 100 | 280 |

| 4 | КП547 | 219…530 | 11,7 | 1 | 34 | 90 | 300 |

| 5 | КП669 | 245…600 | 8…13 | 1 | 47 | 80 | 260 |

| 6 | КП9344 | 1220…1620 | 11…11,5 | 1 | 25 | 15 | 450 |

Also the INTERMASHSTROY company is engaged in repair and modernization of the press equipment of production of the Odessa plant of presses; the Dnepropetrovsk plant of presses; Yamasui, Japan, other serial and unique presses.

Русский

Русский  English (UK)

English (UK)